Quick Guide

- What Exactly Are We Trying to Manage Here?

- The Nuts and Bolts: Core Components You Can't Ignore

- Why Do Supply Chains Keep Breaking? The Usual Suspects

- Building Something Better: A Practical Path to Optimization

- The Tech Toolbox: What's Hype and What's Helpful?

- Answering the Real Questions People Ask

- Looking Down the Road: What's Next for Supply Chains?

You know the feeling. A key supplier misses a deadline. A shipment gets stuck at a port halfway across the world. Suddenly, your entire production line grinds to a halt, customers are angry, and your team is scrambling. It's chaos. And it all comes back to one thing: your supply chain.

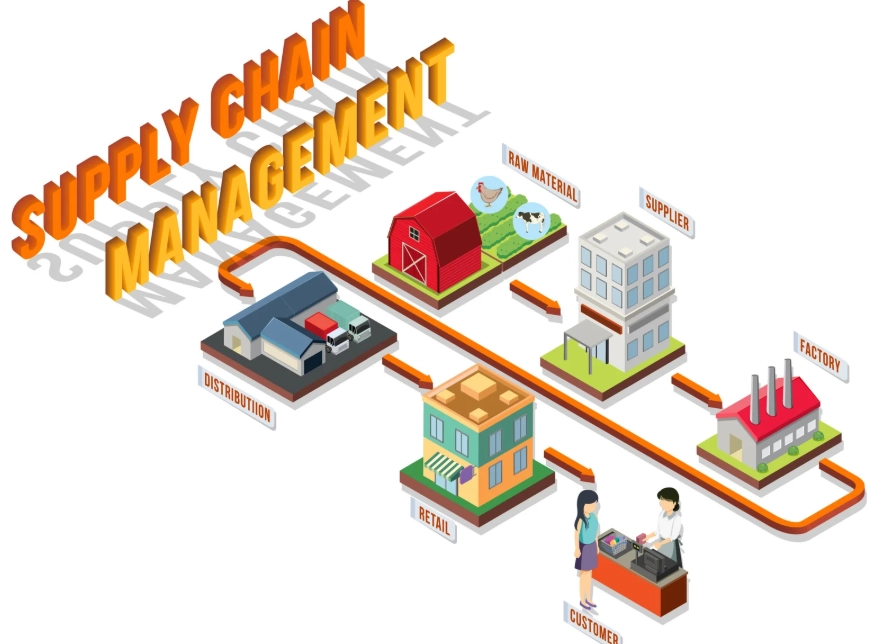

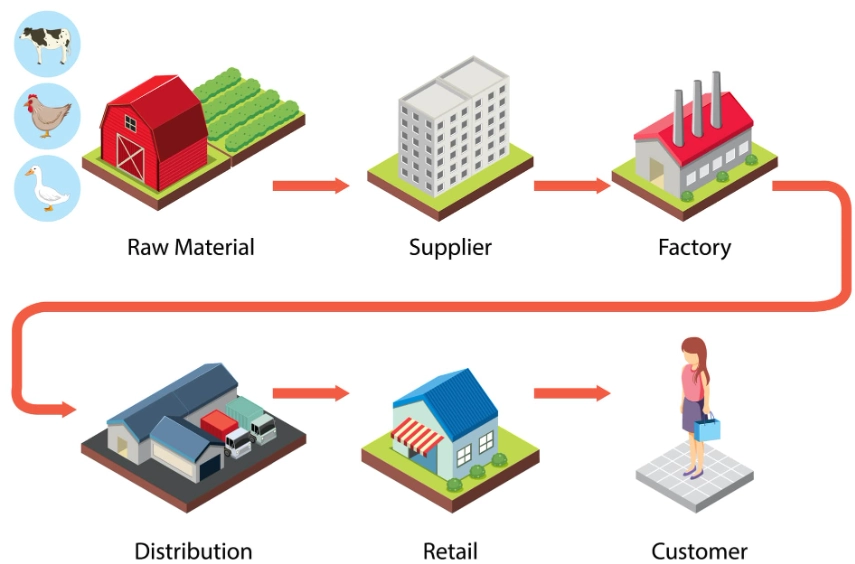

It's not just about moving boxes from point A to point B anymore. A modern supply chain is this incredibly complex, living network. It's your raw materials, your manufacturing partners, your warehouses, your shipping lines, your last-mile delivery guys, and the software that's supposed to tie it all together. When it works, it's invisible. When it breaks, it's a headline.

What Exactly Are We Trying to Manage Here?

Before we dive into fixing things, let's be clear on the scope. When people say "supply chain," they often picture trucks and ships. That's logistics, a critical piece, but just a piece. A true end-to-end supply chain strategy touches everything.

It starts with figuring out what you need to buy and who you're going to buy it from (procurement and sourcing). Then it's about making the thing efficiently (production). After that, you've got to store it smartly (warehousing) and finally get it to the person who bought it (fulfillment and logistics). Woven through all of this is planning—trying to predict demand so you don't have too much or too little of anything. It's a giant, continuous loop.

And the goal? It's a balancing act.

You're trying to minimize cost while maximizing speed, reliability, and flexibility. Oh, and you need to do it all sustainably and ethically now, too. No pressure.

The Nuts and Bolts: Core Components You Can't Ignore

Let's break down the main parts. Think of these as the essential gears in your machine.

The Big Five Supply Chain Pillars

- Planning & Forecasting: This is the brain. Using data (historical sales, market trends, even weather) to guess what you'll sell and when. Get this wrong, and everything else is just expensive guesswork.

- Sourcing & Procurement: Finding and buying the materials and services you need. It's not just about getting the lowest price; it's about finding reliable partners who won't disappear on you.

- Manufacturing & Production: Turning raw materials into finished goods. Efficiency here is king, but so is quality control. A fast line that makes defective products is worse than useless.

- Logistics & Warehousing: The muscle. Storing inventory and moving it around. This is where transportation costs, warehouse rents, and delivery times become very real numbers on your P&L statement.

- Returns & Reverse Logistics: The part everyone forgets until they have to deal with it. How do you handle products coming back? It's a huge cost center and a massive customer experience opportunity (or disaster).

I see a lot of businesses hyper-focus on one or two of these and treat the others as afterthoughts. Big mistake. A superstar logistics operation can't save you from terrible planning. A brilliant forecast is worthless if your supplier can't deliver the materials.

Why Do Supply Chains Keep Breaking? The Usual Suspects

We've all lived through the recent disruptions. But honestly, most supply chain problems aren't caused by once-in-a-century pandemics. They're more mundane, and therefore more preventable.

Here’s a quick list of the classic culprits:

- Demand Volatility: A viral TikTok video can spike demand 1000% overnight. Can your supply chain handle that? Most can't.

- Supplier Reliability: Your supplier's problem becomes your problem. Their financial issues, labor disputes, or quality lumps land directly in your lap.

- Logistical Bottlenecks: Port congestion, truck driver shortages, customs delays. The physical movement of goods is fragile.

- Inventory Mis-management: Too much cash tied up in slow-moving stock, or not enough of the fast-selling items. It's a capital efficiency nightmare.

- Lack of Visibility: This is the big one. If you don't know where your stuff is, when it's arriving, or what condition it's in, you're flying blind. You can't manage what you can't see.

And visibility isn't just about tracking a shipment. It's about seeing into your supplier's supplier. If a conflict disrupts rare earth mineral mining in one country, how does that affect the chipmaker who supplies your component manufacturer? That depth of insight is what separates reactive companies from proactive ones.

Building Something Better: A Practical Path to Optimization

Okay, enough about the problems. How do we build a supply chain that doesn't fall apart at the first sign of trouble? Let's talk about real, actionable steps. This isn't about overnight transformation; it's about consistent improvement.

Step 1: Map Your Current Supply Chain (Yes, All of It)

You'd be shocked how many business leaders can't draw their own supply chain network beyond their tier-1 suppliers. Grab a whiteboard (or a huge piece of paper). Start with your end product and work backwards. List every component, every material, every sub-assembly. Note who supplies it, where they are located, and what alternative sources exist (if any). This map alone will reveal your single points of failure. It's tedious, but it's the most important homework you'll do.

Step 2: Diversify Your Supplier Base

Putting all your eggs in one basket is a strategy for scrambled eggs. I'm not saying you need five suppliers for every tiny screw. But for critical components, you need options. This could mean:

- Multi-sourcing: Using two or more suppliers for the same item.

- Nearshoring/Reshoring: Bringing some production closer to home. It might cost more per unit, but the reduced risk and faster lead times can be worth it. The conversation around supply chain resilience has made this a top priority for many.

- Dual-sourcing from different regions: One supplier in Southeast Asia, another in Eastern Europe. A disruption in one region won't take you completely offline.

This step costs money and requires more management effort. But the cost of *not* doing it when a primary supplier fails is almost always higher.

Step 3: Invest in Visibility Technology

This is where tech stops being a buzzword and starts paying rent. We're talking about tools that give you a real-time, digital view of your inventory and shipments across the entire chain.

Key tools to look at:

- Supply Chain Control Towers: These are software platforms that aggregate data from all your different systems (ERP, warehouse software, carrier tracking) into one dashboard. It's like mission control for your logistics.

- IoT Sensors: GPS trackers on containers, temperature/humidity sensors for sensitive goods. You get real-time location and condition data, not just a "last scanned" update from two days ago.

- Blockchain for Provenance: Still emerging, but powerful for industries where authenticity and ethical sourcing matter (pharma, luxury goods, food). It creates an unchangeable record of a product's journey.

Don't try to boil the ocean. Start with one pain point. Is it not knowing your in-transit inventory? Start with a basic tracking integration. Is it forecasting? Look at a dedicated planning tool. The goal of supply chain optimization is incremental gains that add up.

The Tech Toolbox: What's Hype and What's Helpful?

The software landscape is overwhelming. Every vendor promises to revolutionize your operations. Let's cut through the noise with a straightforward comparison.

>Large, complex organizations needing deep integration. >Powerful but often clunky and expensive. Implementation is a marathon, not a sprint.>Any business with a warehouse (physical or 3PL). >A game-changer for efficiency and accuracy. A modern WMS pays for itself quickly in labor savings and error reduction.>Companies with high shipping spend across multiple carriers. >Excellent for finding the best rates and routes. Can significantly cut freight costs.>Businesses with seasonal products, volatile demand, or long lead times. >Moves you beyond "spreadsheet guessing." Even a 10% improvement in forecast accuracy can dramatically lower inventory costs.>High-value, time-sensitive, or perishable goods. >No more calling carriers for updates. You see problems (like a refrigerated truck failing) before the customer does.| Technology | What It Actually Does | Best For... | My Realistic Take |

|---|---|---|---|

| ERP Systems (SAP, Oracle) | The central nervous system. Manages core business processes (finance, HR, inventory) in one place. | ||

| Warehouse Management Systems (WMS) | Optimizes storage, picking, packing, and shipping within a warehouse. | ||

| Transportation Management Systems (TMS) | Plans, executes, and optimizes the physical movement of goods. | ||

| Demand Planning Software | Uses algorithms and AI to forecast future customer demand more accurately. | ||

| IoT & Real-Time Tracking | Provides live data on shipment location, condition (temp, shock), and estimated arrival. |

My advice? Don't buy tech for tech's sake. Start with the problem: "We have too much dead stock," or "Our shipping costs are out of control." Then find the tool that solves that specific problem. A simple, well-used tool is better than a "comprehensive suite" that nobody understands.

Answering the Real Questions People Ask

Looking Down the Road: What's Next for Supply Chains?

So where is all this heading? The buzzwords are "digital," "autonomous," and "predictive." Here's my translation.

We're moving towards supply chains that can largely run and heal themselves. Think AI that doesn't just forecast a disruption but automatically reroutes shipments around it. Think self-driving trucks for long-haul routes (closer than you think). Think digital twins—virtual copies of your physical supply chain where you can simulate the impact of a hurricane or a new product launch before it happens.

The role of people will shift from manual execution and firefighting to analysis, relationship management, and overseeing these intelligent systems. The human touch in supplier negotiations and strategic partnerships will become more valuable, not less.

The bottom line?

Building a robust supply chain is a journey, not a destination. It requires constant attention, investment in the right places, and a willingness to admit where your weak spots are. Start with the map. Have an honest conversation with your team about your biggest single point of failure. Fix that one thing. Then move to the next.

Because in today's world, your supply chain isn't just a cost center in the back office. It's your competitive advantage. It's what lets you deliver when others can't. It's what builds customer trust that lasts long after any marketing campaign is forgotten. And getting it right, well, that's the real work.